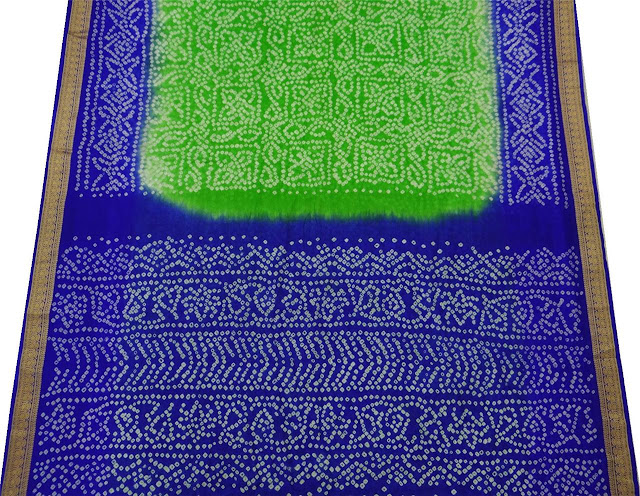

The name ‘bandhani’ (or bandhni) has been derived from the Hindi word ‘bandhan’, which means tying up. In accordance with the meaning of its name, bandhni basically involves tying and dyeing of fabrics.These sarees feature the uniquely created small spots or dots produced as a result of resist-dyeing which generate elaborate patterns on the colored or uncolored base fabric.

|

| Jamnagari Bandhani |

'Gharcholu' "Panetar' and 'Odhani' which is a compulsory part of Gujarati bridal trousseau are special kind of 'bandhani' sarees done in silk or cotton.

|

| Panetar Saree |

|

| Gharchola Saree |

'Lahariya Saree' are among the traditional designs of Bandhani that are very popular the shoppers and tourists. Lahariya saree is one type of Bandhani from Rajasthan where entire length of the cloth is tied instead of small sections to produce diagonal stripes called lahariya (waves). It is said that the fashion for wearing Lahariya was started by the Royal family of Jaipur long ago. Rajasthani women continue this trend and wear these sarees on festivals of Teej and Rakshabandhan.

Besides sarees, bandhani is extensively used in dupatta, chaniya choli,skirts and turbans.

|

| Bandhani Turban |

|

| Laheriya Bandhej Turban |

Technique

The artisan community associated with the art of bandhani making are called as "Rangrez"

Preparation:

As the first step for making bandhani, the cloth is washed and bleached. This is done with the aim of preparing the fabric for absorbing the dyes.

Designing:

Farma is a transparent plastic sheet with small pin holes, on which the design is created first. With the help of these pin holes design is transferred on the cloth.Once the Farma is ready they lay bundle of the cut cloth on the ground.

Then they put Farma on top of it. Then with the help of the colour water and squeeze they transfer the design on cloth. Since the size of the cloth is big, for good transfer, this process requires two people to do it.

Tying:

Once the design transfer is done this transferred cloth is sent to the ladies who do the “Bandhej” or the tying work. She picks up a small portion of the fabric, at a time, and firmly ties a thread around it.

During bandhani printing, the cloth is covered with many tiny knots. The placement of these knots is crucial and per-decided by the printer, as it is these knots only that later form the design, after the fabric is opened. Besides dots, square, waves and stripes are also produced. These bandhani dots are named as per their size and shape.

Bindi- Very small spots without a dark center

Kori- Cowrie shell or a tear-drop shape

Chundadi- Round spots

Ghatadi- Square

Dyeing:

Thereafter, the fabric is dyed.The main colors used in Bandhani are natural. In case two shades are required in the fabric, it is dipped in the light color first. Following this, the areas in which the first dye has to be retained are tied, for resist. Finally, the fabric is dipped in a darker dye. In case, the fabric has to have a number of colors, the dying process is repeated as many times.

Chunri Print Bandhej Sarees:

Everyone must have heard about "Maati ki Chunri" that is offered to the goddess Amba Mata.Chunari is a special technique of fabric dyeing practiced in Rajasthan. It involves a combination of the bandhej(tie-and-dye) process and direct printing.

The fabric is prepared for the dying process by dipping it in water containing equal parts of castor oil and saline earth. The fabric is repeatedly soaked in the solution and dried for about 10 to 15 times, and finally washed with clean water. Wooden blocks containing designs are prepared. The designs are lined with nails. These wooden blocks are pressed against the fabric causing an imprint of designs to be created in a raised form due to the nails. The portions of the fabric, that stand out due to the nails, are tied with a string into knots and coated with a paste that prevents the percolation of a dye. The knots are removed after the fabric is dyed with dyes prepared from natural substances . The non-dyed portions created by the knots form the desired patterns on the cloth. These fabrics are then with thread work embroidery, mirror work or gold brocade.The famous Black Chunari with the red borders is mainly used at the time of Diwali.

The traditional bandhani market has shrunk however, because of the rise of low-cost silk-screened or chiffon imitations.Most modern bandhani sarees are made with larger designs and fewer ties than in the past.